<ul id="ks4ce"></ul> <ul id="ks4ce"></ul> <ul id="ks4ce"></ul>

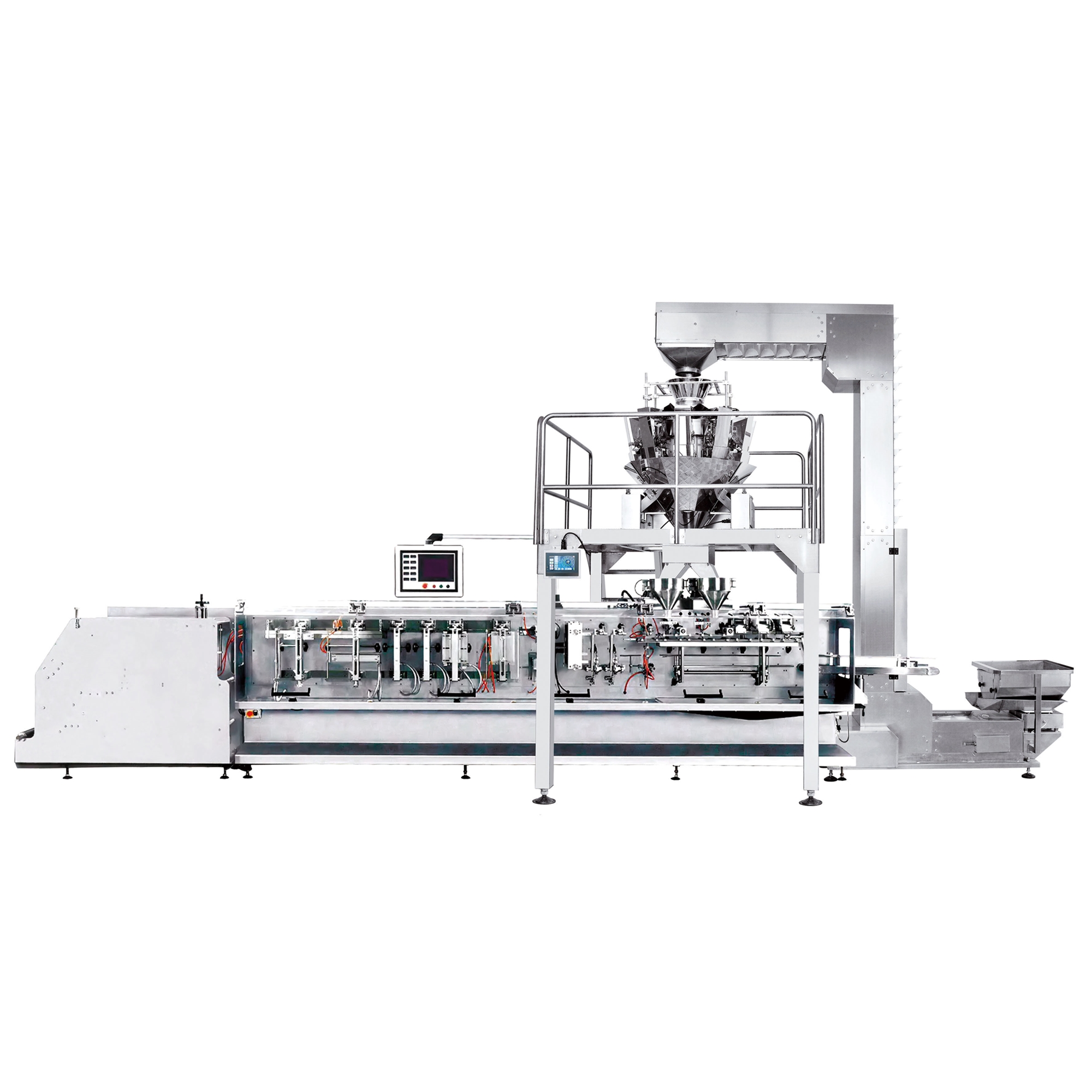

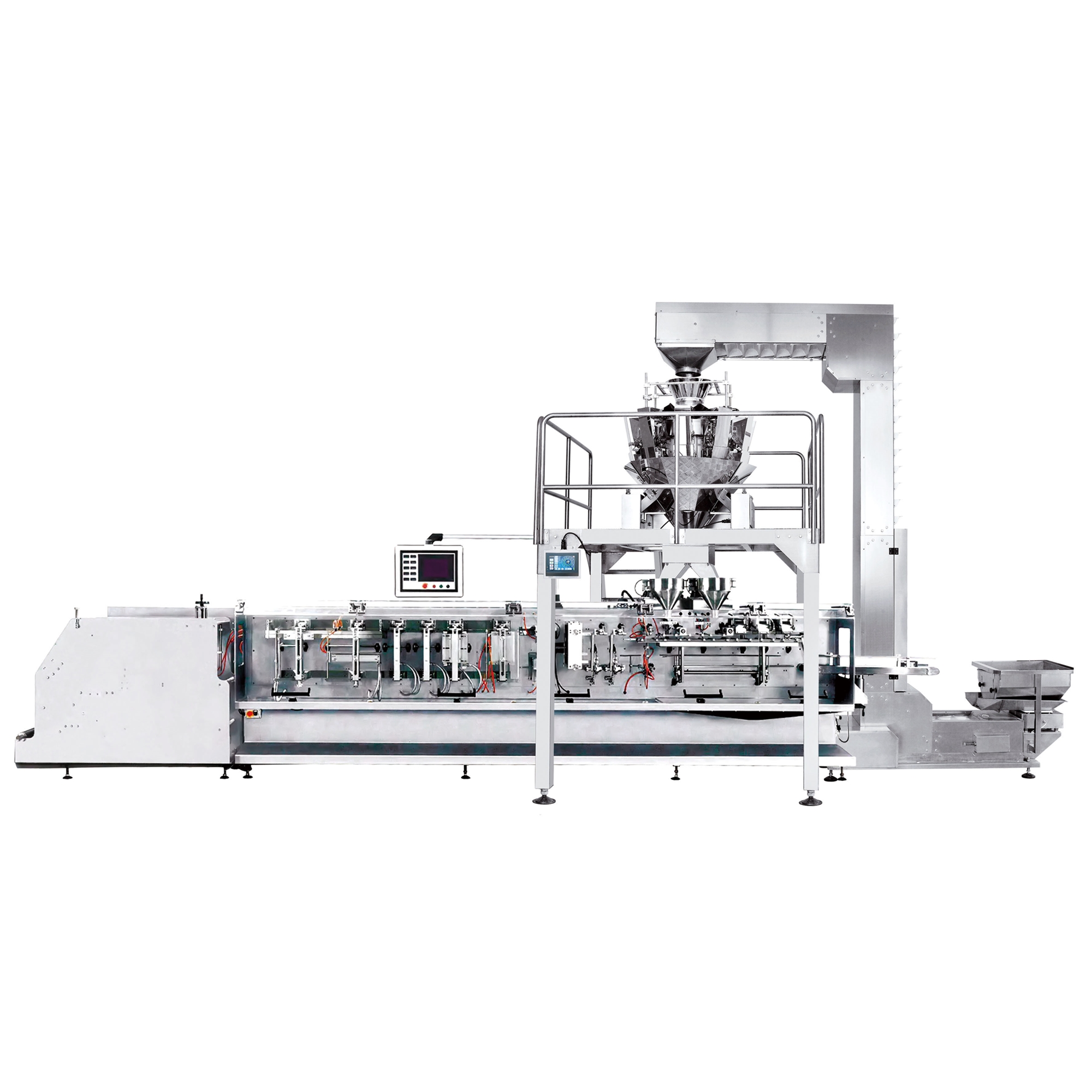

Double inlet Weighing and packing systems is suitable for weighing granule, slice, roll or irregular shape products such as candy, seed, jelly, fries, coffee bean, peanut, puffy food, biscuit, chocolate, net, pet food, small hardware, etc.

1. Fully-automatically completes all the process from feeding, weighing, date-printing and finished products outputting;

2. Wide scope of application, Suitable for various materials.

3. High weighing precision and efficiency.

4. Used for pre-made bag, Stable operation, high speed and high production efficiency, beautiful bag making.

Bag type: 3 side seals bag, 4 side seals bag, flat bag, Flat bag with zipper, Stand up bag with zipper, special flat bag, special stand up bag.

![]()

Reject unqualified products, it can sort the product and make statistics (if already equipped with other weight detection equipment then no need use this machine)

It is used to detect the metal which mixed during the production process. It is suitable to use after finishing packaging (if already equipped with other metal detector then no need use this machine).

It is used to detect the metal which mixed during the production process. It is suitable to use before packaging.It is installed between weigher and packaging machine,space saving (if already equipped with other metal detector then no need use this machine).

It is used to detect the metal and check weight,combined the check weigher with metal detector,save cost and less commissioning and maintenance time.

Used to collect products from the production line,Suitable for production lines that require manual processing or waiting for further packaging operations.

JW-B14 Double inlet Weighing and packing systems for per-made bag including: Vibrator feeder, Z conveyor, Working platform, Multihead weigher, Double inlet horizontal packing machine.